Technical Introduction & Test Summaries

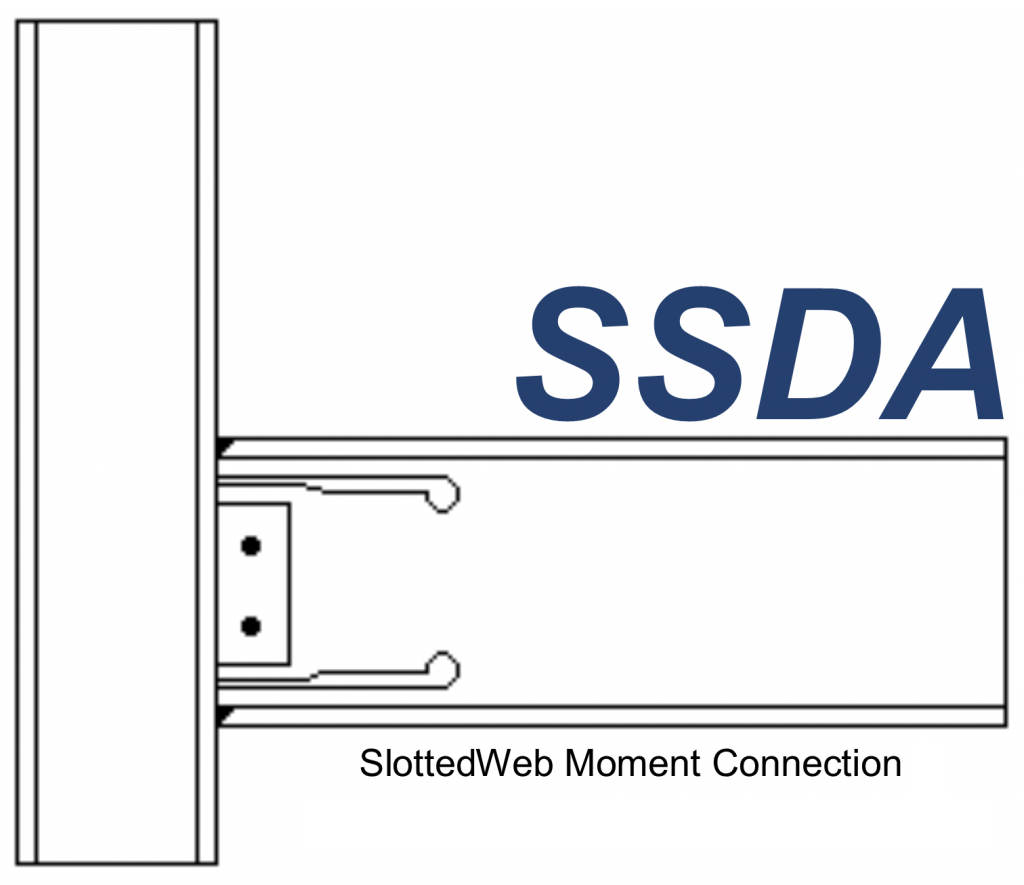

This connection is shown schematically in Figure 1. It is similar to the popular field welded–field bolted beam-to-column moment frame connection, shown in the AISC LRFD and ASD steel design manuals, that has become known as the “pre-Northridge” connection. Based upon surveys of seismic connection damage, modes of fracture, reviews of historic tests, and recent ATC-24 protocol tests in the SAC/FEMA research program, it was concluded by SEAOC (1996 Blue Book Commentary) that the pre-Northridge connection is fundamentally flawed, and should not be used in the construction of new seismic moment frames. Subsequent finite element analyses and strain gage data from ATC-24 tests by Seismic Structural Design Associates, Inc. (SSDA) of this pre-Northridge connection have shown large stress and strain gradients horizontally across and vertically through the beam flanges and welds at the face of the column. These large flange stress and strain gradients are caused by a very large component of the seismic shear, typically 50% or more, that is carried by the beam flanges. It is these flange shear forces that produce a prying moment in the welds and flanges at the face of the column and at the weld access holes that led to the weld and flange fractures and to the column flange divot modes of connection fracture.connec

However, by (1) separating the beam flanges from the beam web in the region of the connection and (2) welding the beam web to the column flange, the force, stress and strain distributions in this field welded-field bolted connection are changed dramatically in the following ways:

- The beam web resists the entire beam vertical shear and its share of the beam moment whereas the flanges resist only moment. Moreover, the SlottedWeb (SW) connection is kinematic so that the connection force distributions are statically determinate and are independent of interstory drift. Full scale low cycle fatigue tests have shown that this kinematic attribute more than triples the fatigue life over non-slotted connections that subject the beam flange/welds to large beam seismic shear forces.

- Since most W sections have a flange to beam modulus ratio of 0.65 < Zflg /Z < 0.75, both the beam web slots and the beam web-to-column flange weldment force the beam web to resist its portion of the total beam moment.

- The beam web separation from the beam flange reduces the large stress and strain gradients across and through the beam flanges and at the weld access hole by permitting the flanges to flex out of plane, which reduces the beam flange/weld prying moment on the column flange. Typically, the elastic stress and strain concentration factors (SCFs) of the pre-Northridge connection, caused by severe local beam flange and/or column flange distortions, are reduced from 4.0 to 5.0 in non-slotted beams down to 1.2 to 1.4, which dramatically reduces the beam flange prying moment and the accumulated plastic strain and ductility demand under cyclic loading. These attributes enhance and extend this connection’s fatigue life to more than triple the fatigue life of non-slotted moment frame connections.

- By allowing the beam flanges to flex out-of-plane, the kinematic slotted connection reduces the limitations on panel zone strength relative to beam strength. These limitations are required for non-slotted unreinforced welded flange connections to provide a balance between yielding of the panel zone and other connection elements to prevent excessive panel zone deformations that result in the kinking of the column flanges that increases the fracture toughness demands on the joint weldments.

- The lateral-torsional mode of beam buckling that is characteristic of non-slotted beams is eliminated. The separation of the beam flanges and beam web allow the flanges and web to buckle independently and concurrently, which eliminates the twisting mode of buckling and its associated torsional beam flange/weld stresses. Elimination of this buckling mode is particularly important when seismic moment frames that are located on the perimeter of the building support the exterior cladding of the building. Even a small amount of twisting of these beams will be reflected as significant visible distortion of the exterior cladding.

- The separation of the beam web and the flange results in biaxial rather than triaxial stress and strain states in the region of the connection, which increases its fatigue life. Moreover, residual weldment stresses are significantly reduced because the slots also provide a long structural separation between the vertical web and horizontal flange weldments.

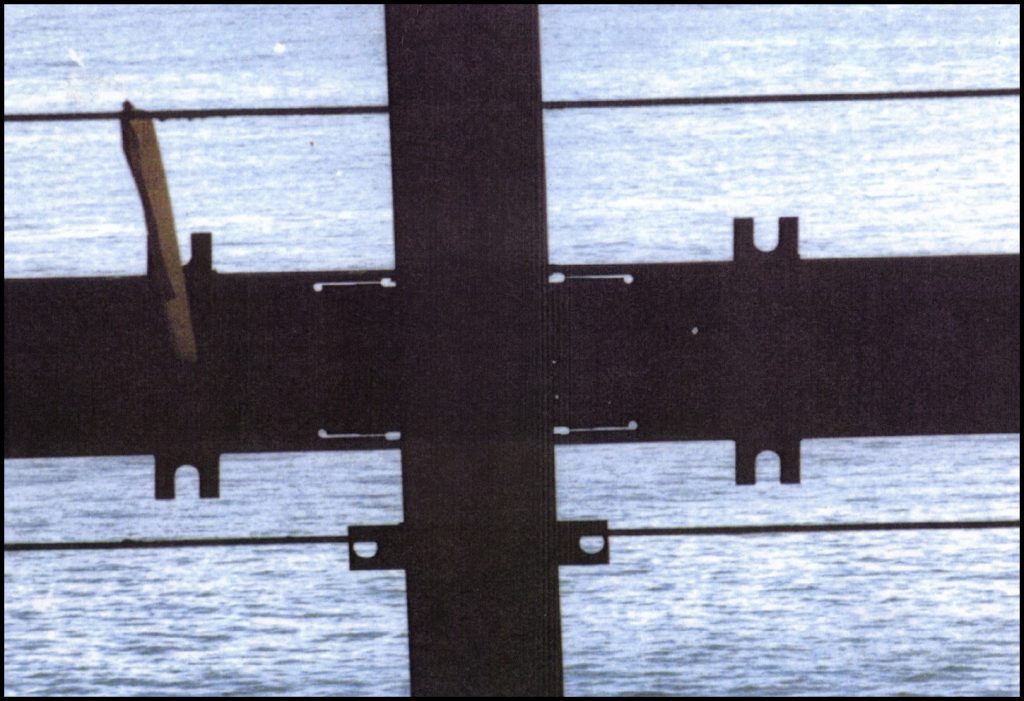

Figure 1

with SF Bay in the Background

The SW connection design rationale that sizes the beam/web separation length, shear plate and connection weldments, is based upon ATC-24 protocol test results and extensive inelastic finite element analyses of the stress and strain distributions and buckling modes. Incorporated in this rationale are the IBC and AISC Load and Resistance Factor Design (LRFD) Specifications and the IBC and AISC Seismic Design Provisions for Steel Buildings and its supplements.

SSDA has successfully completed ATC-24 protocol tests with beams ranging from W27x94 to W36x393 with columns ranging from W14x176 to W14x550. Additionally, successful tests have been completed using W24x94 and W36x170 beams with deep W30 columns. None of these assemblies experienced the lateral-torsional mode of buckling of the beams or columns that is typical of non-slotted beam and column assemblies.

Shown in Figures 2, 3, 4, 5 and 6 are the total plastic rotation hysteresis curves for each of the following ATC-24 assemblies: a W24x94 beam and a W30x132 column, a W36x170 beam and a W30x235 column, a W27x94 beam and a W14x176 column, a W33x141 beam and a W14x283 column, and a W36x393 beam and a W14x500 column. Two of each of these assemblies using current SSDA design rationale were successfully tested and reported in accordance with the current AISC Seismic Provisions for Structural Steel Buildings.

To view the test summaries, click here.

SSDA Tests 23, 24, 25, and 26, (refer to Figs. 2 and 3 above) were made specifically to demonstrate slotted web connection ATC-24 test performance when used with deep columns. These columns were laterally braced only at the top beam flange level to simulate restraint of a concrete filled metal deck. Neither column twisting nor lateral torsional beam buckling occurred during these four successful tests.

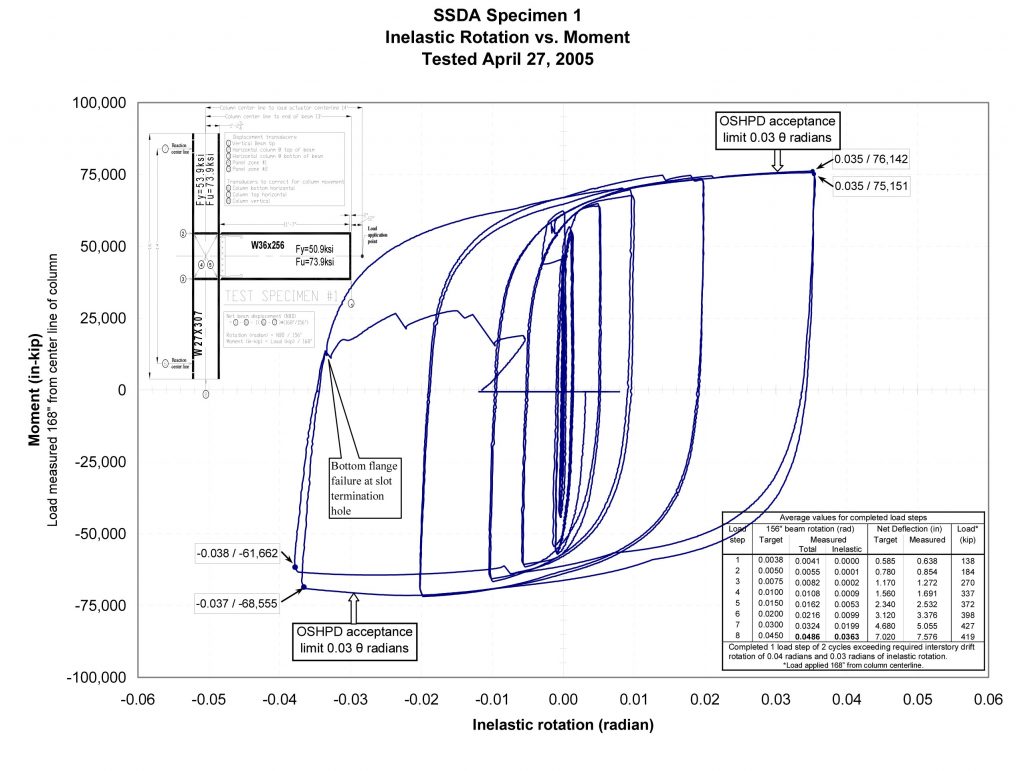

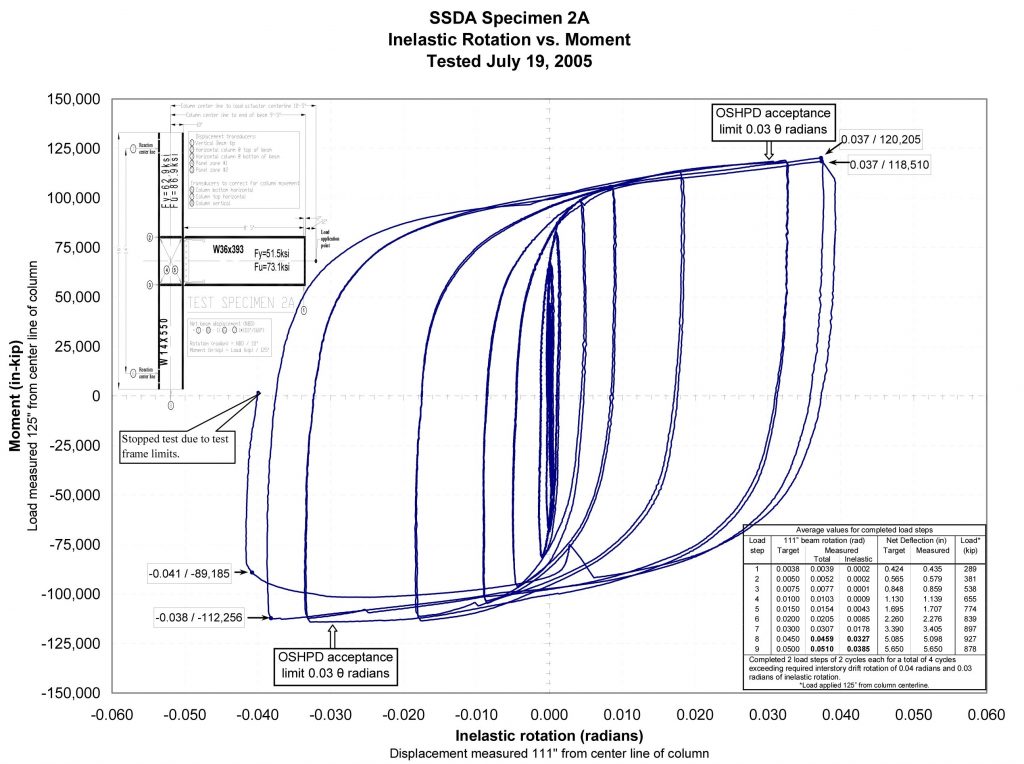

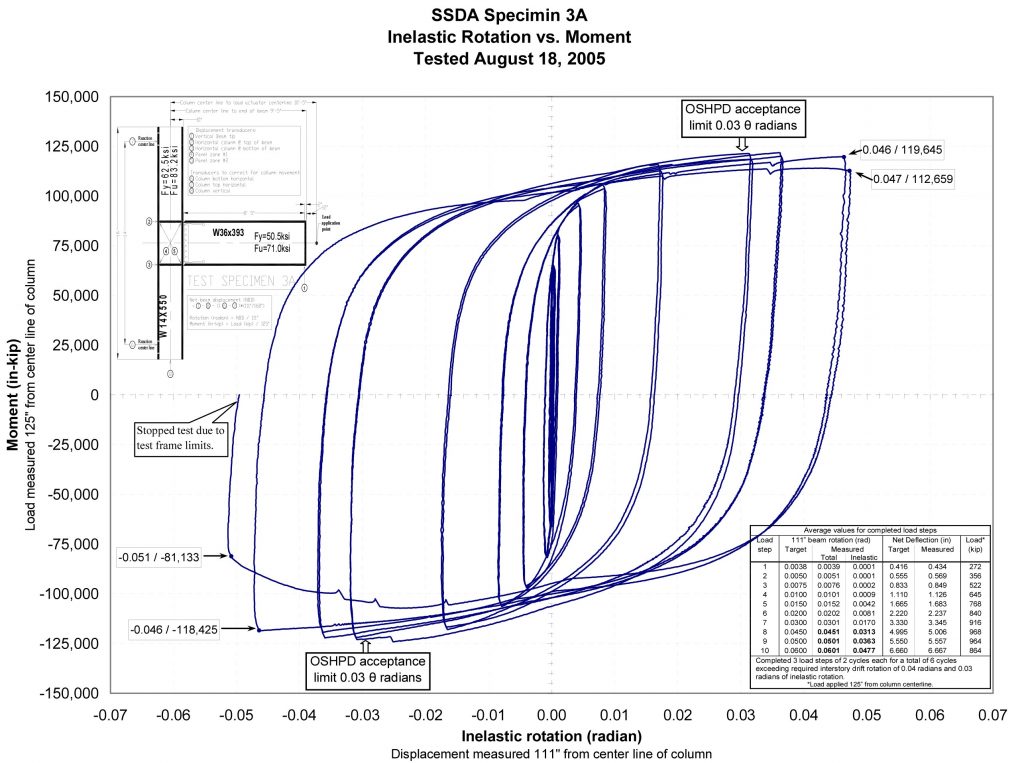

Shown here are the Inelastic Rotation vs. Moment curves for the W36X260 and W36X393 beams. Refer to the Technical Documents section “Additional Approval Reports” for a full description of these OSHPD tests (Specimens 1, 2a, and 3a).

Both analytical studies and ATC-24 protocol tests have demonstrated that the SSDA SW connection designs develop the full plastic moment capacity of the beam and do not reduce the elastic stiffness of the beam. All of the above attributes of this proprietary connection enhance its strength and ductility, which makes it applicable for use in both new construction and the retrofitting of existing connections in seismic moment frames.

Currently SSDA has completed or contracted for the design of the SW connections in over 800 new buildings. Included in these are a 40 story building in San Francisco, a 32 story building in San Diego, and a 20 story building in Salt Lake City. Six buildings have been retrofitted including a 10 story office building in Burbank and a three story medical office building in Granada Hills. The Office of Statewide Health Planning and Development (OSHPD) has approved the SW connection designs for use in hospitals in California.

To view SW seismic force distributions, click here.